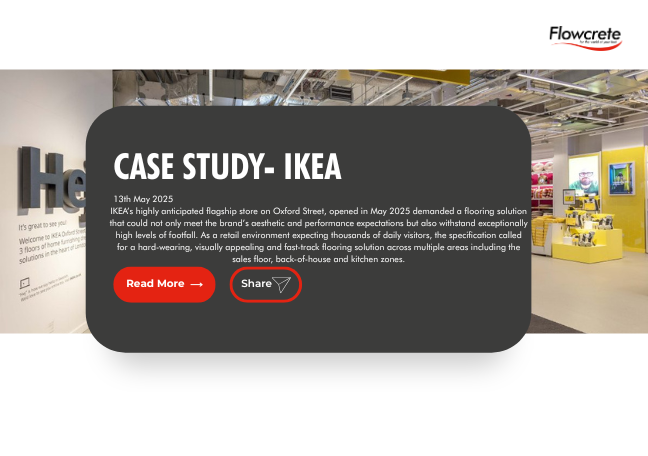

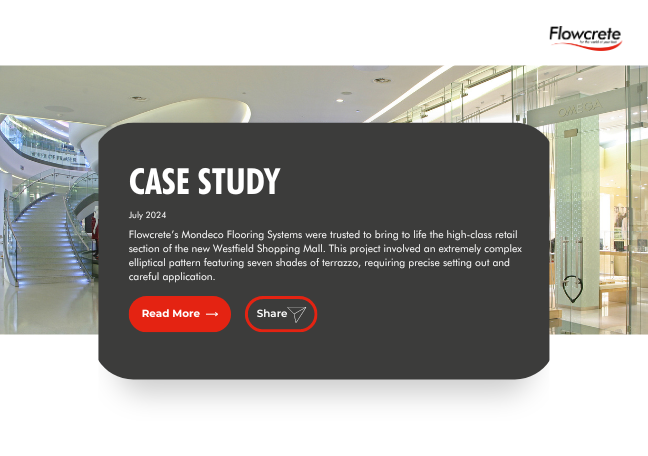

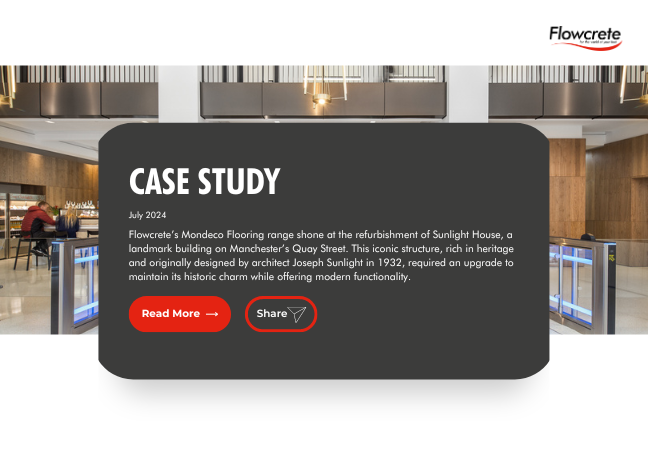

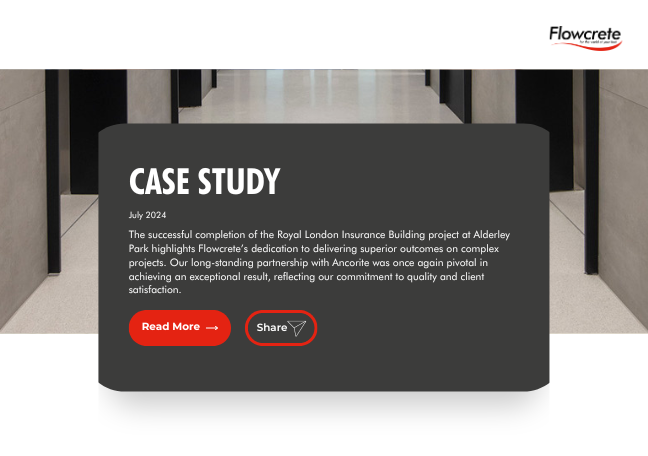

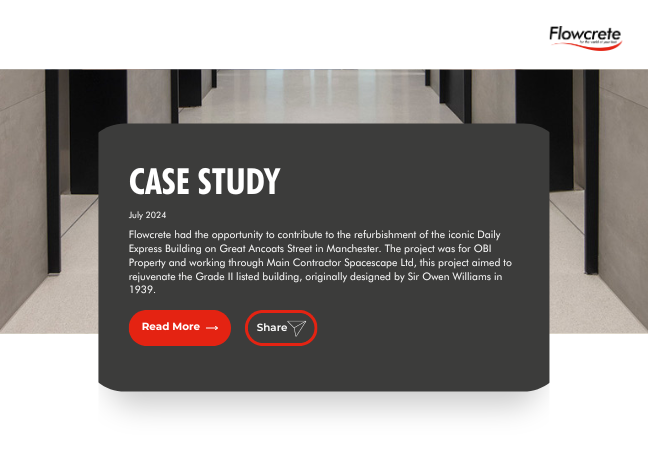

Case Studies

Take a look at our case studies to find out how we deliver flooring solutions to the most complex industrial and commercial environments. These are just some examples of how we have helped specify the most suitable floor finishes for Food & Beverage, Industrial Facilities, Commercial Venues, and more. Get in touch and let us help you find the right flooring specification for your project!